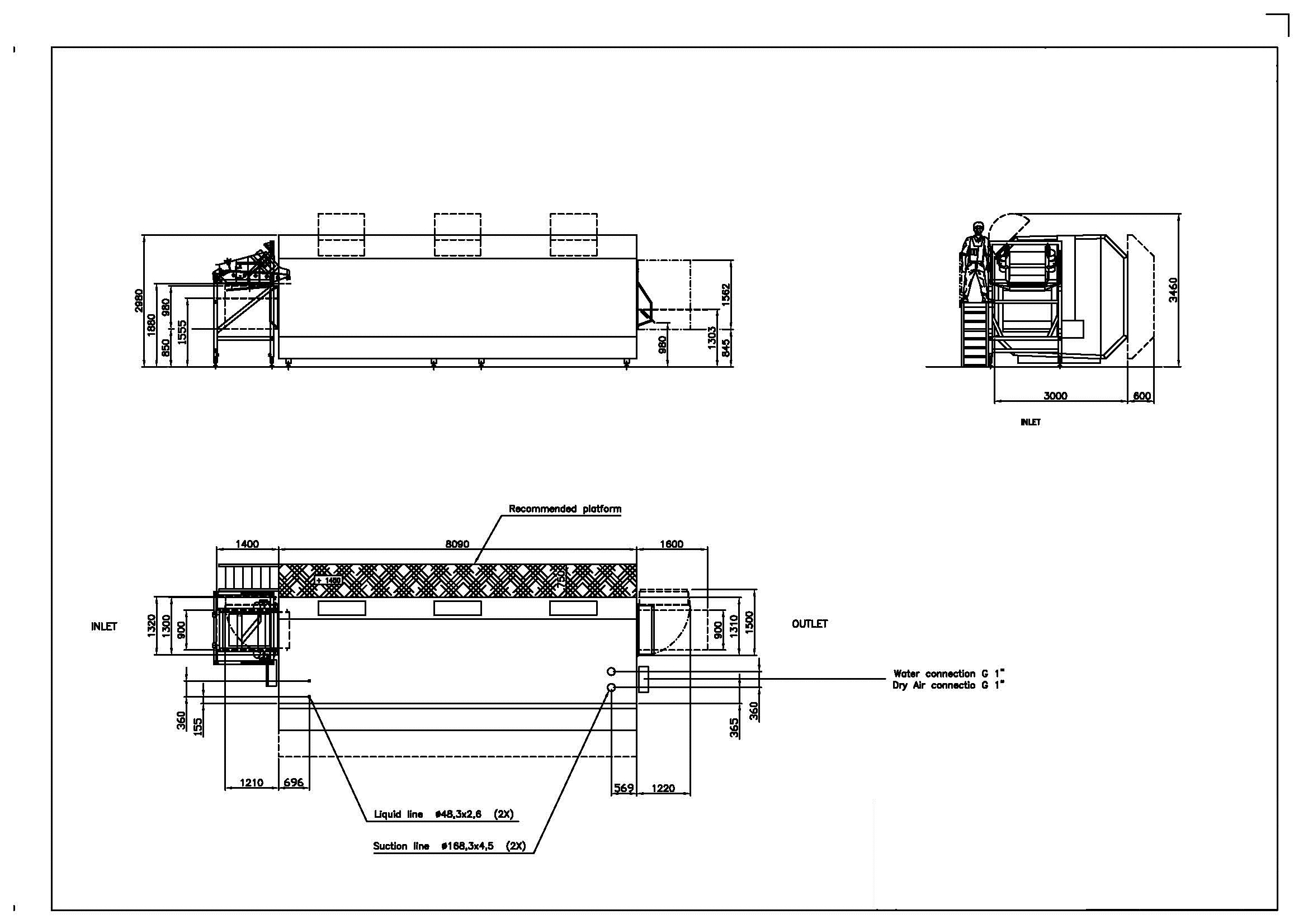

FS001: OCTOFROST MODEL 7/2 IQF:

OCTOFROST IQF - IQF FROST AB Mod. 7/2 LH Ser. 7031 (approximately 3,700 H) tunnel blast freezer unit (4,650 Kg/Hr) incorporating mono-block (hermetic) housing unit (8090 mm long x 3000 mm wide x 2900mm high); ANSCO product infeed bedplate system (2200 mm long x 800 mm wide); blast freezing and plenum zones comprising 7 x 12-bladed blast fans (2 x primary 22 kW and 5 x secondary 11 kW); removable bedplate system; coil fin (NH3 evaporator); snow removal system (SRS); clean in place (CIP) foam generator system; SIEMENS blast freezer operator’s control panel (touch screen); and work platform (7600 mm long x 700 mm wide), including associated safety devices, drive assemblies, NH3 components, pipework, interfaced electrical controls and distribution systems, main and sub-frame assemblies, fittings and connections. Manufactured in 2006:

FS002: FRICK SCREW COMPRESSOR:

FRICK Mod. FWFII 316 H Ser. 0123 (3,706 H) rotary screw compressor system (R717) incorporating FRICK Ser. SGC28130192 rotary screw NH3 compressor set complete with WEG Mod. AGA 315C Ser. 1506831005 induction drive motor (375 kW); WAYNESBORO Mod. HOS-36 Ser.155086 matching tube and coil inner chamber high pressure (HP) vapour/oil separator/filter vessel; HANSEN Mod. NEAP Ser. AA598 non-electrical auto purging system; liquid supply modulator; POWER ELECTRONICS Mod. V50650 Ser. 39060193 digital soft starter unit; and I.C SWITCHGEAR Mod. Micro Logix 1200 Ser. 2711-K3A17L1 programmable logic control system, including associated

safety devices, drive assemblies, NH3 components, pipework, main and sub-frame assemblies, fittings and connections (D.O.M. 2006):

FS003: BALTIMORE AIR COIL CONDENSER:

BAC Mod. VC1C231 Ser. 06J0875 evaporative condenser unit (cooling tower) incorporating evaporator condensing pump system; WELDTRADE ENGINEERING Mod. WTLR06212 Ser. IS1261006 liquid column; CWC Mod. Digichem-AB2-V Ser. 0603025871 cooling tower dosing system; POWER ELECTROINCS Mod. SD45039 450 Series Ser. 05102200409 variable speed drive unit, including associated safety devices, drive assemblies, NH3 components, pipework, main and sub-frame assemblies, fittings and connections (D.O.M. 2006) Note. New variable speed drive unit to be installed:

FS004: WELDTRADE LPR:

WELDTRADE ENGINEERING Mod. WTSS05200 Ser. IS1251006 low pressure (LP) receiver system incorporating liquid pump system; spare (CAM 4) liquid pump set; and oil rectifier system, including associated safety devices, drive assemblies, NH3 components, pipework, main and sub-frame assemblies, fittings and connections (D.O.M. 2006) Note. All NH3 pressure vessels fully charged (approximately 1 Tonne NH3); M & I certified and current – as verified by refrigeration service contractor; No Chlorofluorocarbons (CFC) refrigerants noted during site visitation 13th and 14th September 2017:

FS005: ABAC AIR COMPRESSOR:

ABAC Mod. Formula 22 Ser. 2939980001 (6,356 H) rotary screw (22 kW) air compressor set (package type) complete with 4 x CSC SRL (500 Litre) WMS constructed vertical air receivers and MTA Mod. SDA-025/AA Ser. 32.633/06 desiccant air dryer unit, including associated safety devices, auto controls, pneumatic pipework and reticulation, fittings and connections (D.O.M. 2006):

FS006: ABAC AIR COMPRESSOR:

ABAC Mod. Formula E 22 Ser. 2910940001 (9,081 H) rotary screw (22 kW) air compressor set (package type) complete with 4 x EURE (270 Liter) WMS constructed vertical air receivers and TRIDENT Mod. Dryspell 100P Ser. 2K6/11S5645 desiccant air dryer unit, including associated safety devices, auto controls, pneumatic pipework and reticulation, fittings and connections (D.O.M. 2006):